|

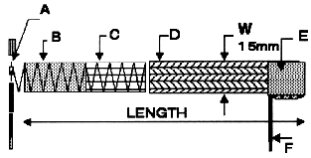

Type n

A. High quality dip soldered joint. |

|

ACH/n

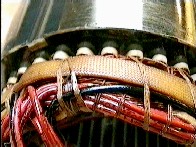

cure and then a second coat applied, to ensure that the

heater and windings form a homogenous mass to provide good thermal conductivity.

APPROVALS: |

||||||||||||||||||

|

FITTING INSTRUCTIONS 1) Accommodating Standard Length Motor Heaters The heating unit is designed for inclusion in the impregnation process. It is possible to apply Type ACH/n heaters to a number of different winding diameters on the principle that the length of a particular heating unit or units will cover at least 70% of the circumferential distance and if an overlap occurs, that the client will ensure 5 mm separation between the adjacent turns of the heating unit. Large electric motors may require a number of heaters on each end of the stator pack, but very large motors have the advantage that the surface to which the heaters must be fitted is reasonably smooth and continuous which improves the heat transfer efficiency. Thus a number of heaters may be conveniently fitted at each end of a large motor, and any individual heater need only cover a semi-arc or a part circumference. In this case the heating units are usually fixed by pieces of adhesive-backed glass fibre electrical insulation tape placed across the heaters at convenient intervals. 2) Fitting of Motor Heaters Usually motor heaters are laced onto the stator pack end turns during the manufacturing process. This is normal practice for smaller motors, but care must be taken to allow for the shrinkage of the lacing material during the impregnation process. Many polymer-based materials which are used in the construction of modern motors suffer severe contraction during the varnishing process which incorporates various heating cycles, and the tension thus created in the lacing at its final state may be sufficient to damage or cut-through the heating unit. Alternative fixing methods use an adhesive-backed glass fibre electrical insulating tape of suitable temperature rating which is applied over the heating unit so as to fix the heating unit firmly in place. This adhesive tape must be considerably wider than the heaters. Such fixing methods are relatively inexpensive and convenient and also suitable for retro-fit operations, provided the instructions given in 3) below are complied with. On larger motors a number of heaters may be required on each end in order to provide the total nominal power input, and in this case, they may be fixed by overwrapping with adhesive tape as above, or by localised fixings with strips of adhesive tape placed across the width of the heater unit. The heater shall be connected to earth while the motor windings is high voltage tested. The heater shall be high voltage tested to earth at 2000V r.m.s. for 1 minute 3) Retro-fitting of Heaters It should be noted that Type ACH/n motor heaters are the only semi-fabricated product made by RTL and they are designed as components for incorporation into the motor impregnation process. Thus if they are fitted later in the production programme, or are used as retro-fit devices, it is essential that two successive coats of varnish are applied by brush and allowed to cure before the units are commissioned in order to provide the necessary degree of thermal conductivity and moisture proofing to the heater. |

|

Component Approval No. Ex 94Y4457U: Motors and generators that comply with BS 5000: Part 1b 1985 + Amendment 1 to 4. Component Approval No. Ex 98Y4345U: Motors and generators that comply with EN 50021: 1998. SCHEDULE OF LIMITATIONS |

|

II 3G EEx nA II

II 3G EEx nA II