FOR ELECTRIC MOTORS

AND GENERATORS

The ACHIF range of electric heating tapes provides low cost protection against condensation within rotating electrical equipment. Typical applications would be electric motors, generators and alternators which operate in damp or wet conditions. Examples would include off shore, shipboard and marine equipment, dockside cranes, well pumps and all equipment operating in a tropical environment. Specifying anti-condensation heaters at the design stage can save the expense of costly rewinds and down time.

FITTING RECOMMENDATIONS

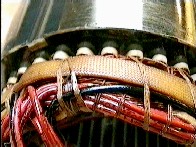

The heating unit is designed for inclusion in the impregnation process. The OEM or the Rewinder fits the selected ACH heating tape to the end turns of the motor stator pack by lacing or by use of suitable adhesive insulating tape applied longitudinally over the full length and width of the heater prior to varnish impregnation. If lacing is employed care must be taken to allow for the shrinkage of the lacing material during the impregnation process.

A motor heater is usually sized to fit around the stator pack, covering at least 70% of the circumference.

When a heater is selected that is longer than the circumference care must be taken to keep the overlap separated from the original turn by 5 mm minimum to avoid hot spots.

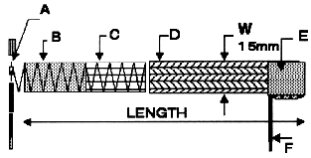

A. High quality dip soldered joint.

B.

80/20 Ni Cr or 56/44 heating element. Glass fibre tape carrier.

C.

Polyester backed adhesive tape, thermosetting adhesive.

D. Glass fibre

braid insulation.

E. Acrylic adhesive backed glass fibre tape

insulation and cold leads reinforcement.

F. 500mm ColdLeads 19/0.15

ETFE(Tefzel) insulated equipment wire.

ACH/F

One or more heater units are fitted to each end of the motor as required to apply the desired total electrical energy.

A separate terminal block is usually provided for the heater units. A change-over contact wired to bring in the heater when the motor is de-energized must be provided on the starter.

Total power is not normally critical and standard ACH units may be fitted on industrial motors over a wide range of supply voltages.

| ACH/F Standard Range | |||||

| ACH Ref | Length | Volts | Watts | Frame Size | |

| in | mm | ||||

| 00a 00b 0a 0b 1a 1b 2a 2b 3a 3b 4a 4b 5a 5b 6a 6b 7a 7b 8a 8b |

8 8 12 12 17 17 27 27 27 27 30 30 40 40 42 42 58 58 67 67 |

203 203 305 305 432 432 686 686 686 686 762 762 1016 1016 1067 1067 1473 1473 1702 1702 |

110 220 110 220 110 220 110 220 110 220 110 220 110 220 110 220 110 220 110 220 |

8 8 22 25 27 26 21 21 40 40 25 26 39 42 50 54 67 65 103 99 |

80 90 100 112 132 & 160 180& 200 225& 250 280 280 315 |